PRODUCTS

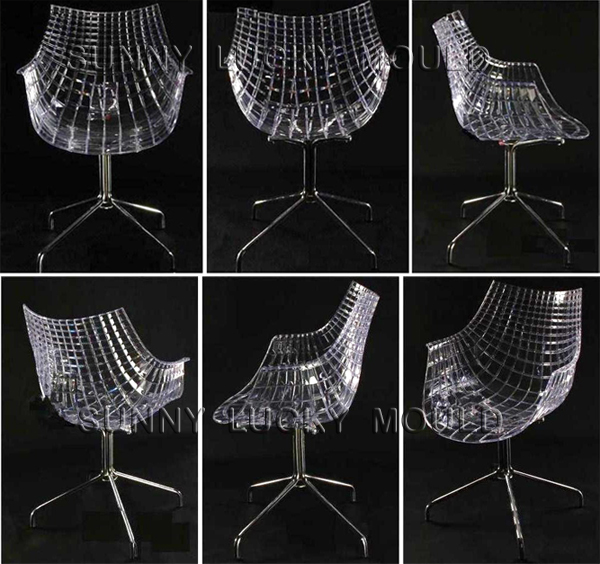

- Table- chair- bench mould

- Basket and bucket mould

- Thin-wall container

- Trash bin

- Tray mould

- Pipe fitting mould

- Auto part mould

- Electrical appliance mould

- Preform mould

- Cap mould

- Bottle mould

- Blowing machine

- Others

- Thermoplastic elastomers

TEL : +86-576-84287688

FAX : +86-576-84202858

E-mail :sales@sunnyluckymould.com

Food container

Detail

Specifications

Thin-wall plastic container mould

With high-standard steel

With a long mould life

With competitive price

Significantly reduces your production cost

|

Place of origin: |

Zhejiang China (China mainland) |

|

Brand name: |

SL (Sunnylucky) |

|

Production method: |

Plastic injection |

|

Product material: |

PP/ABS/PS/PMMA/PC/PE/NYLON/Others |

|

Product wall thickness: |

0.6-0.3mm |

|

Mould material: |

H13/P20/NAK80/2316/S50C/S45C/718/Others |

|

Mould base: |

LKM/others |

|

Gate type: |

Pin point nozzle desiging, no need to cut the tail |

|

Ejection type: |

Air valve/Stripper |

|

Core pulling system: |

Hydraulic cylinders |

|

Cavity: |

Single/Multi |

|

Surface finishing: |

Texture (MT standard)/Mirror polishing |

|

Runner: |

Hot |

|

Mould heat treatment: |

Tempering/Quenching/Nitriding/Hardness 48-52HRC |

|

Mould life: |

1000000--shots |

|

Design software |

UG/CAD/CAM/CAE/Pro-E/Solid work/others |

|

Processing: |

High speed CNC/Standard CNC/High speed carve/EDM/Wiring-cutting/others |

How to make a thin-wall mould

1. Material

1) Core and cavity with 2316/H13 to avoid mould or water pipe hole getting rusty.

2) Front & back mould with 2344/S136/DC53/GS767 etc. After heat treatment, hardness can reach 2344HRC50-52, S136HRC48-52, DC53HRC48-52, GS767HRC50-52

3) Most insert are with S136, 083, 2344 plus heat treatment. Others which close to nozzle uses beryllium cooper for better cooling.

4) Guide sleeves on the mould base has to add standoffs, which hardness shall reach HRC48—52。

2. Mould design

1) Before mould opening the front mould needs to be 0.05-0.1mm pushed out, to make blow and product drop easier.

2) Air out groove shall be set between insert and insert.

3) All mould cooling system shall be as much as possible, including all inserts.

4) Choose most suitable material to make the mould. On the basis of no deforming under pressure, the material shall be as small as possible, to make the mould weight as light as possible.

5) Core needs to be 1/2 bigger than product when putting on the back mould. Air out insert required.

6) Front mould shall be round. Positioning as circumferentially uniformly distributed. To help mould heating and less deforming.

3. Processing

1) All cores and parts needs rough machining before heat treatment. Normally leave 0.25-0.5mm margin.

2) After heat treatment, all parts outer shape and right angle will be grinded.

3) After precision grinding, there has to be both self-check and QC, before moving on to CNC machining. Apart from calibration, middle-check of smoothess of surface is also conducted. If not smooth enough, 0.05 margin is required for EDM. Core needs to be matched properly with base, to ensure good thermal conductivity.

4) After precision machining, self check and QC check. When no problem then move to final grinding.

Related ProductsMore >>

简体中文

简体中文 English

English